Engineering a House That Lives, Breathes, and Dies

In the first steps toward designing a ‘living’ building, researchers grow bricks out of fungus and bacteria that can self-heal, sense and respond to each other, and decompose when no longer needed.

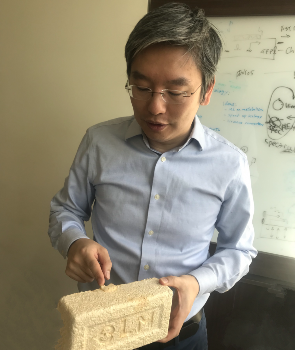

On a recent morning in the lab, Harris Wang turns over a buff-colored brick in his hands. It looks and feels like Styrofoam, but is actually close kin of the common mushroom. To create it, Wang poured fungal mycelium and hemp stalks into a mold and added water. A week later, out popped a fully-formed brick, imprinted with the letters ELM, for engineered living materials.

An expert on the microbiome, Wang normally focuses on programming microbes in the human gut to make probiotics. But more recently, his attention turned to soil-dwelling bugs and harnessing them to make lightweight, programmable materials that biodegrade at the end of their lifetime. His inspiration? The plants and trees around us.

“The bricks-and-mortar infrastructure we have today is inert,” said Wang, an associate professor of systems biology and pathology and cell biology at Columbia University Irving Medical Center. “If it breaks down, you have to patch it up, tear it down, and rebuild. It doesn’t respond to the environment. A tree, on the other hand, harvests energy from the sun. It can heal itself, produce fruits for animals to eat, and it decomposes when it dies.”

Building materials out of microbes wasn’t top of mind for Wang until he crossed paths with Ecovative, a company near Albany, N.Y., that makes compostable packaging, among other products, from mycelium, the branching roots of common fungi. Normally Ecovative’s mycelium-based products are sterilized before leaving the factory. But scientists wondered if they could impart new functionalities in their materials by keeping the fungus and its bacterial microbiome alive.

Fungus in its own right has some intriguing capabilities, including the ability to self-heal and self-fuse for mortarless construction. But it’s difficult to tinker with in a lab. By contrast, the bacteria that has evolved to live alongside it is easier to program and create new functionalities. And so, Wang was asked if he could identify the dominant microbes in Ecovative’s packaging as a first step toward engineering a living material.

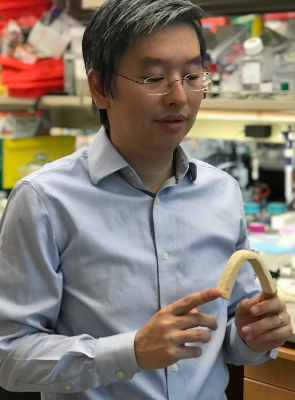

In a four-year collaboration with Ecovative and its principal scientist Damen Schaak, Wang and his lab would turn out living fungal-bacterial composites molded into bricks, blocks, and even boxes with lids that open and close on living hinges. They also showed that these living bricks could be programmed to talk to each other.

In a recent paper in Nature Materials led by Ross McBee, (GSAS’22), Wang and his colleagues identified the dominant microbe in Ecovative’s fungal packaging as Pantoea agglomerans, a microbe associated with plants and insects that’s even been edited to secrete a toxin into mosquitos as an anti-malarial agent.

The researchers also reported the results of their experiments, which included bricks grown from bacteria programmed to alternately produce and receive a molecular signal to fluoresce. It’s this last bit—the ability to make living sensors—that they’re especially excited about. Living sensors could detect cholera in the water, they say, or carbon monoxide and other pollutants in the air. “The idea is to create smart bricks with new functionalities,” Wang said.

Smart bricks have other benefits. They can be grown from commonly found waste materials; in addition to hemp stalks, the researchers have tried feeding the mycelium shredded paper and even drop-ceiling tiles. And once the bricks have outlived their usefulness, they can be composted, like a pile of leaves. “They gracefully biodegrade back into the environment,” McBee said.

The bricks also have the ability to self-heal. Punch a hole into one, add water, and the mycelium grows back. Lay two bricks side by side, add water, and watch them fuse together, creating building blocks for mortarless construction. “The material even becomes stronger,” McBee added.

One downside of living materials is their unpredictability. On a recent tour of the lab, Wang and McBee pointed to a bumpy layer of mushroom sprouting from one of their bricks, presumably after the brick came into contact with water.

This spontaneous outgrowth brings up another selling point: The bricks, technically, are safe to eat. Chinese medicine uses the same type of mycelium growing in these living bricks.

“This is probably not something you'll see rolled out next hurricane season. But it’s part of a new and interesting way of thinking about the built environment; one that’s more active, responsive, reactive, and, well, alive, than what we have today.”

The researchers see plenty of applications for their lab-grow materials. Temporary houses made of living bricks or folding panels could be grown quickly in a disaster-relief area, where clay bricks, lumber, and other building materials may be scarce. Similar structures could be grown on a space station or even Mars. “You could build fungal self-supporting structures without any mortar or nails, just local materials,” said McBee, who now co-leads a startup called TômTex that makes a sustainable leather alternative from shrimp-shell waste.

“This is probably not something you'll see rolled out next hurricane season,” he added. “But it’s part of a new and interesting way of thinking about the built environment; one that’s more active, responsive, reactive, and, well, alive, than what we have today.”

The project was funded under DARPA's Engineered Living Materials program.